Understanding Custom Hydraulic Equipment

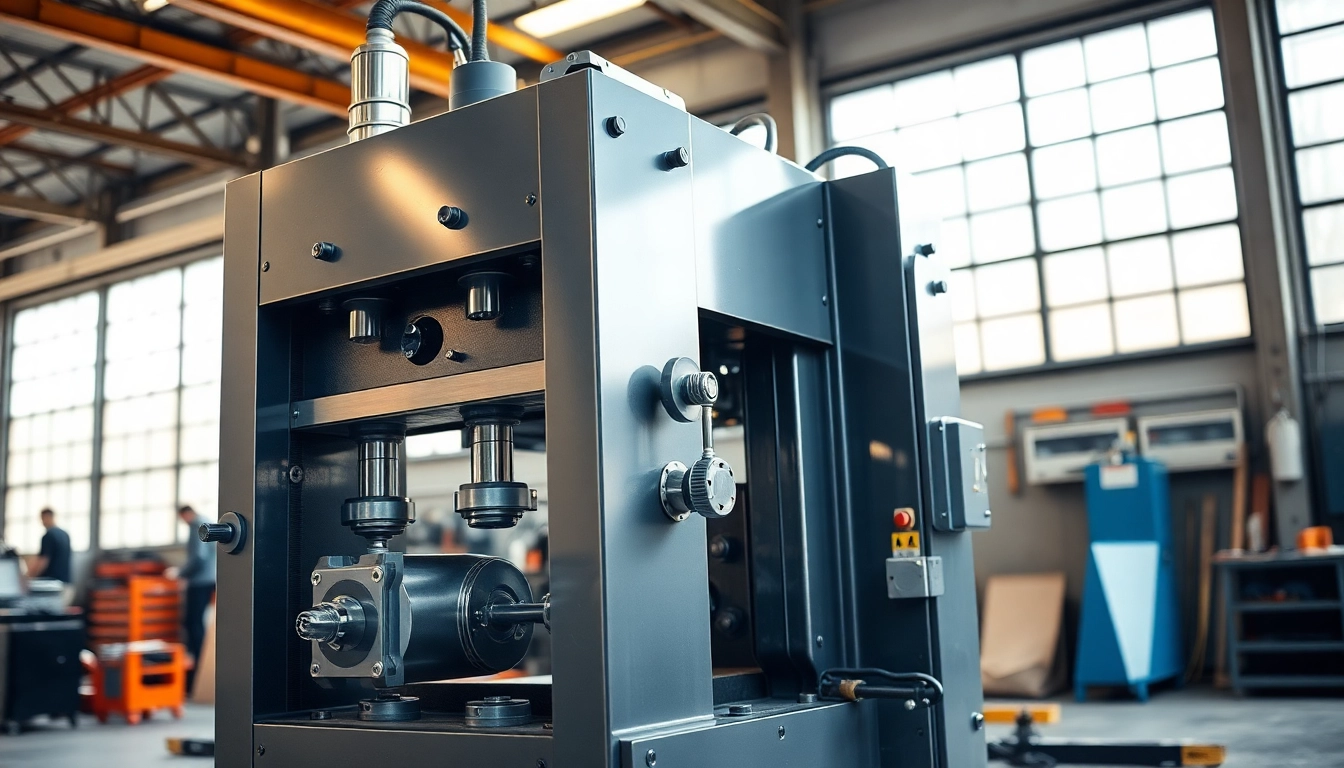

Hydraulic systems play a crucial role in various industries, providing the necessary power for heavy equipment and machinery. At the heart of these systems lies custom hydraulic equipment, tailored to meet specific operational requirements. This ensures efficiency, safety, and performance across different applications. The demand for custom hydraulic equipment has surged, thanks to its ability to enhance productivity and execute specialized tasks that standard solutions may not cover.

What is Custom Hydraulic Equipment?

Custom hydraulic equipment refers to hydraulic systems or components designed and manufactured to meet specific needs of an operation or project. Unlike off-the-shelf solutions, these systems are tailored to integrate seamlessly with existing machinery and optimize functionality. Industries often seek custom solutions when they require equipment that can operate under unique conditions, produce specialized output, or fit within particular spatial constraints.

Key Components and Their Functions

Understanding the essential components of custom hydraulic equipment is crucial for appreciating its capabilities:

- Pumps: Generate hydraulic fluid flow and pressure, essential for power generation.

- Actuators: Convert hydraulic energy into mechanical work, such as moving parts or lifting objects.

- Valves: Regulate the flow and direction of the hydraulic fluid, allowing for control over system operations.

- Filters: Remove contaminants from the hydraulic fluid to ensure its longevity and efficiency.

- Reservoirs: Store hydraulic fluid for system operation and maintain the necessary pressure within the system.

Why Choose Custom Solutions?

Custom hydraulic equipment provides a strategic advantage over standardized systems. By enabling companies to tailor equipment to their specific needs, these solutions can offer excellent compatibility with existing frameworks and enhance overall performance. Moreover, customization allows for the integration of advanced technologies that can significantly improve operation efficiency.

Benefits of Custom Hydraulic Equipment

Improved Efficiency and Performance

One of the primary advantages of custom hydraulic equipment is the potential for improved efficiency. Designed to meet specific operational needs, these systems can reduce downtime and enhance productivity. For example, tailored hydraulic solutions can improve the speed and precision of machinery, leading to faster output and reduced wastage. Companies often report greater throughput and optimized workflows when implementing custom designs.

Cost-Effectiveness Over Time

While the initial investment in custom hydraulic equipment may be higher than off-the-shelf options, the long-term savings can far outweigh these costs. Custom designs often lead to reduced maintenance expenses, fewer breakdowns, and longer equipment lifespan. Additionally, efficient operation can lead to significant energy savings, making custom solutions a cost-effective choice over time.

Enhanced Safety Features

Custom hydraulic equipment can be designed with enhanced safety features tailored to specific operational risks. This includes integrated monitoring systems, pressure relief mechanisms, and optimized fluid flow designs. By prioritizing safety within design specifications, businesses can minimize the risk of accidents and ensure a safer working environment for employees.

Design Considerations for Custom Hydraulic Equipment

Evaluating Operational Needs

Before embarking on the design of custom hydraulic equipment, a thorough evaluation of operational needs is essential. This includes assessing workload requirements, environmental conditions, and specific project goals. Understanding these factors helps engineers create equipment that not only meets current demands but is also versatile enough to accommodate future changes.

Material Selection and Durability

The materials selected for custom hydraulic equipment significantly impact its performance and longevity. It is essential to choose materials that can withstand the stresses of hydraulic operation, resist wear and tear, and perform well in various environmental conditions. For instance, corrosion-resistant materials may be paramount in humid or chemical-heavy environments, while robust alloys might be necessary for high-pressure applications.

Compliance with Industry Standards

Compliance with industry standards is non-negotiable when designing custom hydraulic equipment. This not only ensures safety and reliability but also guarantees that the systems will be recognized and accepted across different jurisdictions. Familiarizing oneself with relevant regulations can help prevent design issues and facilitate smoother adoption during implementation.

Common Applications of Custom Hydraulic Equipment

Use in Manufacturing Industries

Custom hydraulic equipment is extensively utilized in manufacturing for tasks such as material handling, assembly processes, and machinery operation. In manufacturing plants, hydraulic systems streamline operations by automating repetitive tasks, allowing for increased production rates and improved product quality.

Applications in Construction

In the construction industry, custom hydraulic equipment is vital for powering various equipment like excavators, cranes, and loaders. Tailored hydraulic systems can enhance the performance of these machines, providing the necessary torque and lifting capabilities essential for large-scale projects. For example, custom designs ensure that machines can handle specific site conditions and job requirements.

Hydraulic Equipment in Automotive Services

Custom hydraulic equipment also plays a crucial role in automotive services, particularly in workshops where specialized tools such as hydraulic lifts and presses are used. These systems allow for quick and effective vehicle maintenance, making it easier to lift heavy components, apply precise pressure, and ensure accurate alignments during repair processes.

FAQs About Custom Hydraulic Equipment

How long does it take to design custom hydraulic equipment?

The timeframe typically ranges from a few weeks to several months, depending on complexity and specific requirements.

Can custom hydraulic equipment be adapted for different uses?

Yes, it can be designed with versatility in mind to meet variable operational requirements across different applications.

What maintenance is required for custom hydraulic equipment?

Regular inspection, fluid changes, and systematic checks are essential for optimal performance and longevity of the system.

Is it more expensive to get custom hydraulic equipment?

Initial costs may be higher, but long-term savings often outweigh these due to improved efficiency and reduced maintenance needs.

Are there warranty options for custom hydraulic equipment?

Most manufacturers provide warranty options, which can vary based on equipment type and specified customizations.